The Lean Start is 80% funded by IDA Ireland and Enterprise Ireland.

The Lean Start is designed to give companies who are considering implementing lean thinking into their businesses an opportunity to experience a short engagement with a lean consultant who together will complete an internal lean project. The relatively small project will demonstrate how engagement with an independent consultant can deliver benefits and is an opportunity to consider what a Lean Plus programme might look like. Companies that complete the Lean Start are encouraged to continue their journey via a Lean Plus. Lean Starts also provide the necessary time to prepare a more detailed Lean Plus and Lean Transform application.

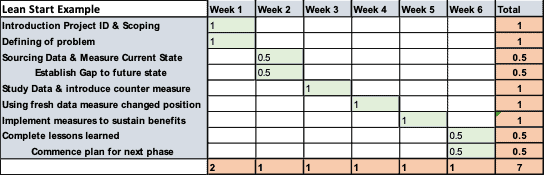

The improvement project chosen for the Lean Start will focus on key pain points within the organisation and include only the key personnel from the area. The Lean Start should be completed in 7-9 weeks.

The Lean Start costs €6300 and is funded by €5,000 by IDA Ireland and Enterprise Ireland.

“PSE Power engaged LBS Partners in a Lean Start programme to assist us in starting our Lean journey. LBS has been an integral part of our transformation as we embark on this operational excellence journey. I would highly recommend LBS as a partner for any operational excellence programme a company is considering.”