What is 6S?

Have you ever been in the middle of a job and not been able to finish because you can’t find a particular tool? Have you ever run out of printer ink because nobody knew they needed to order replacements? Can’t find that file you were working on last week? Did it delay you or even prevent you from finishing the job? Frustrating, isn’t it?

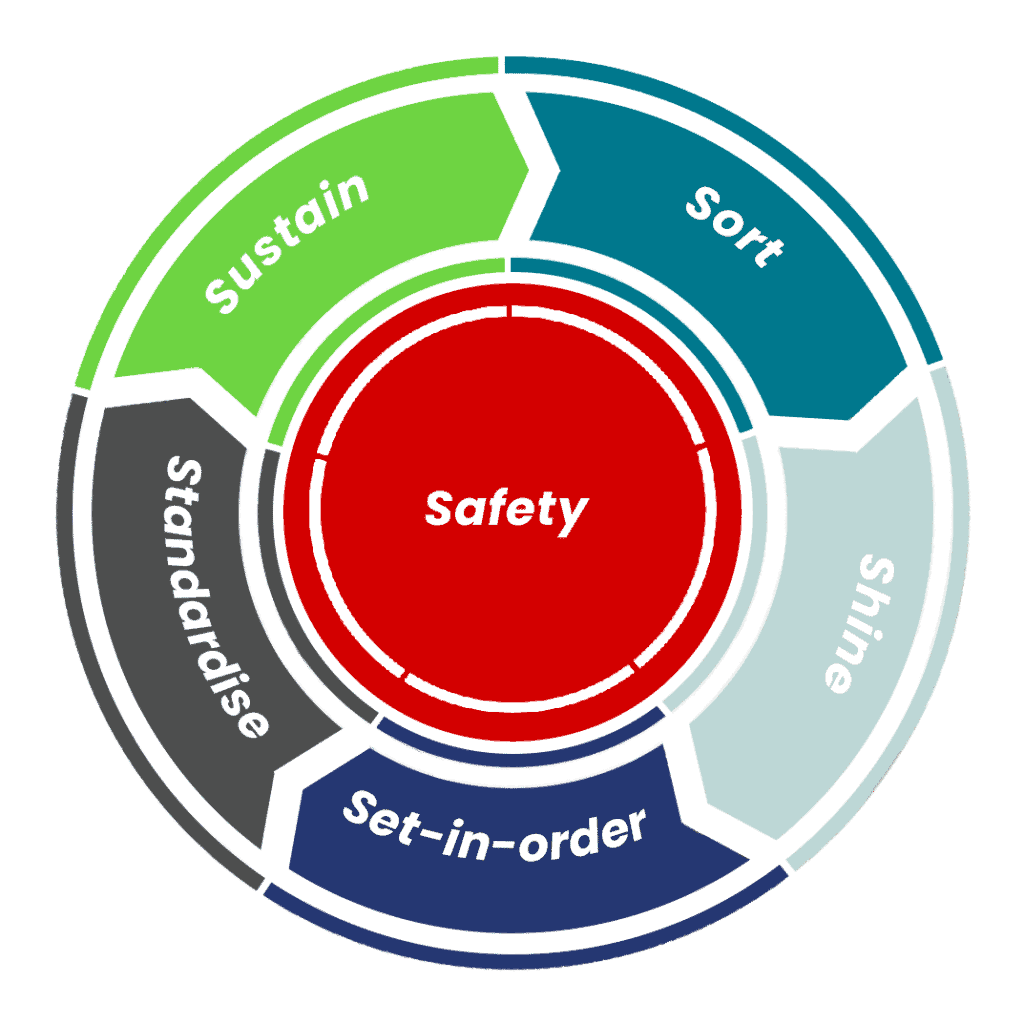

You may then be interested in learning about a Lean tool called 6S or Workplace Organisation. So what is 6S? We define 6S as a Lean process improvement technique that aims to optimise efficiency in the workplace.

It is a series of steps used to arrange work areas to enhance Safety, Performance and Cleanliness. Notice the emphasis on the workplace, as 6S is applicable to all work environments, not just the manufacturing floor, though it did originate there. The six S’s stand for six words which describe the steps included in the workplace organisation programme:

- Safety

- Sort

- Set-In-Order

- Shine

- Standardise

- Sustain

You may already be familiar with 5S and wonder what the difference is between 5S and 6S, well it’s just the emphasis on safety, making Safety First.

SAFETY

Safety First – The most important consideration in Workplace Organisation is to create and sustain a safe working environment. The welfare of the people working in the workplace is the primary concern. Implementing the Safety 6S step involves identifying the hazards or risks in the workplace and putting measures in place to mitigate the risk to employees.

Look for:

Obvious things like slip and trip hazards e.g. extension cords.

Electrical risks such as broken sockets or those with excessive extension cords/plugs.

Make sure all fire extinguishers are clear and ready for use.

When you’ve completed the SAFETY step there should be no obvious risks in the workplace and where necessary, safety signage should be in place to highlight unavoidable risks to employees and visitors.

SORT

The purpose of this step is two-fold:

To remove all unnecessary items from the workplace and to ensure you have all materials, tools, and equipment to do the job. Equipment can mean a laptop, pen, a printer some paper etc.

Examples of unnecessary items include unsafe or defective items, obsolete or duplicate things.

Necessary items are those used for daily work or regularly (weekly for example).

Don’t just think in terms of physical things, the principles of 6S can equally apply to the digital world, you should SORT your digital files, back up files where needed and delete those you don’t need anymore.

At the end of the SORT step, you should have removed all clutter from your workplace and clearly identified what you do need to complete your work.

SET-IN-ORDER

As the old saying goes, there should be a home for everything, and everything should be in its home.

The purpose of the SET-IN-ORDER step is to take the things you identified in the SORT step and arrange them in the best way to help you do your job.

In the physical world there are many tools you can use to optimise your layout, such as:

Motion mapping – track the movement of people and things through the workplace, redesign the layout to reduce the wastes of MOTION and TRANSPORT.

Labeling – Use common sense to label things to make them easily identifiable, use pictures where relevant.

Floor Taping – Mark the position where things should be, you’ll generally find that once you show where they belong, they’ll stay there.

Outlining/shadow-boards – Used widely for example to set out tools in a drawer to store them securely and make them easily available for use. Equally applicable to stationery, pens etc.

Colour-coding – If things belong together or you want to distinguish what they’re used for, labelling them with the same colour. Think of fire extinguishers, labelled with a different colour to indicate the type of fire they’re used on.

In the context of the digital space, a logical system for identifying and labelling your files, establishing a logical directory structure will make files easy to locate eliminating the waste of time looking for them.

Again,

There should be a place for everything, and everything should be in its place.

SHINE

This just boils down to the central tenet:

Keep everything clean and ready for use.

“Ready-for-use” means there are no broken pieces of equipment, the copier isn’t jammed, all the lights are working, the door handle isn’t hanging off the door, you’ve got all five wheels on your nice desk chair. It isn’t all about large complex pieces of machinery. It’s what you encounter every day in the office.

Remember, the best time to see dents and scratches on your car is when you wash it, cleaning leads to inspection and early detection of problems.

In the office consider implementing a clean desk policy. In practice, at the end of the day employees should clear their desks of all clutter, papers, etc. Really think before you print that e-mail. If you don’t need it, shred it. Consider the paperless office, in addition to making the office look better you’ll save on the cost of paper and the time wasted re-ordering it.

A clean desk policy has three main aims:

- To ensure the workplace looks professional

- To help comply with data protection (GDPR) requirements

- To encourage better organisation and productivity

STANDARDISE

The culmination of implementing the previous four steps. Implementing 6S establishes the basic standard for performance, setting a baseline that is progressed through the process of continuous improvement. Standards are generally defined photographically, once you’ve removed the clutter and organised your space in the best manner for you, photograph it. This sets the basic standard. At the end of the working day, return the workspace to your standard.

Just remember, just because it’s the standard today, doesn’t mean it should stay that way forever. Consider how it could be improved, one small thing at a time. The job may change, improve the layout correspond.

SUSTAIN

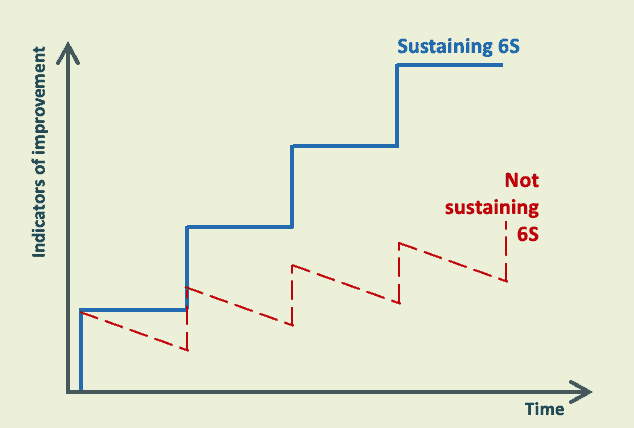

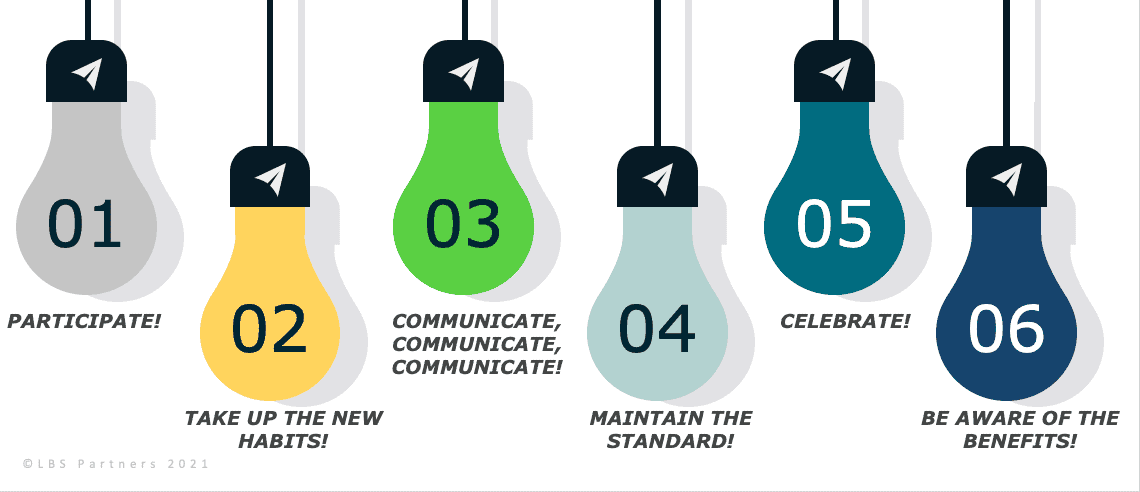

Now we come to what can be the most difficult of the 6S steps, the Sustain step. It can be very satisfying taking a step back and taking the opportunity to re-layout your workspace, but how do you sustain the change? How do you maintain the gains made and prevent old habits from dragging back to your old behaviours?

There are many ways of sustaining the improvements made. Some examples include:

Posters – act as a reminder to all.

Displays – for example using “before” and “after” photos to demonstrate improvements made.

Intranet/Newsletters – Providing updates on ongoing projects.

Pocket manuals – which give an easy reference on 6S to all employees.

Promotions – assign a day, week or a month devoted to 6S and Continuous Improvement.

Examples– arrange visits to other organisations which have successfully implemented 6S.

One of the main ways to sustain the change is to initiate a series of audits. Once the basic standard has been established and the photographic standard documented an audit plan can be put in place. The purpose of the audit is to check 6S compliance and feed into the notion of continuous improvement by highlighting areas for improvement. We audit to see where we are, see where we’re going, to help, assist, advise, monitor, and recognise achievement.

So, these are the six steps of the 6S process. You’ll have seen by now that these are very simple, not “rocket science” but the benefits they bring cannot be overestimated.